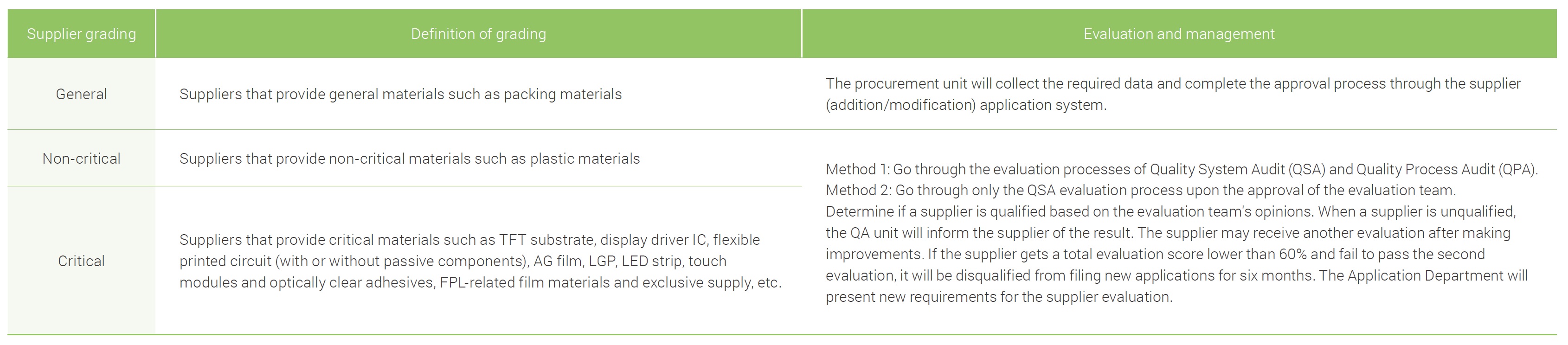

Supplier Classification and Grading

To provide principles for the operations such as the development, evaluation and approval of material suppliers, and properly keep track of the quality and timeliness as confirmed by the suppliers to leverage the effectiveness of supplier cultivation, E Ink has, based on the material properties and in consideration of the difficulty levels and risks of acquisition and supply, classified the direct materials on the Bill Of Material (BOM) into three categories: general material, non-critical material and critical material. This is helpful for us to enter into cooperation agreements with the suppliers, evaluate the suppliers, and manage the suppliers.

Furthermore, the definition of critical supplier grading is annually reviewed. FPL materials and Sole Source materials are planned to be included into the scope of critical materials in 2022.