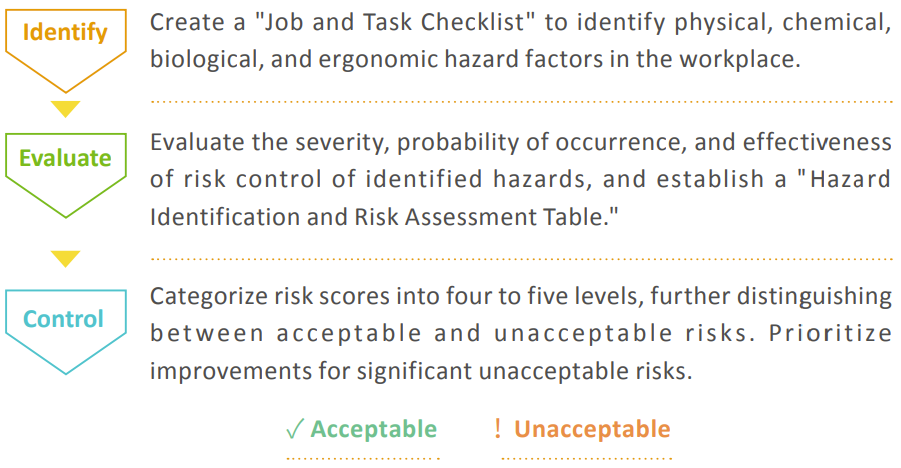

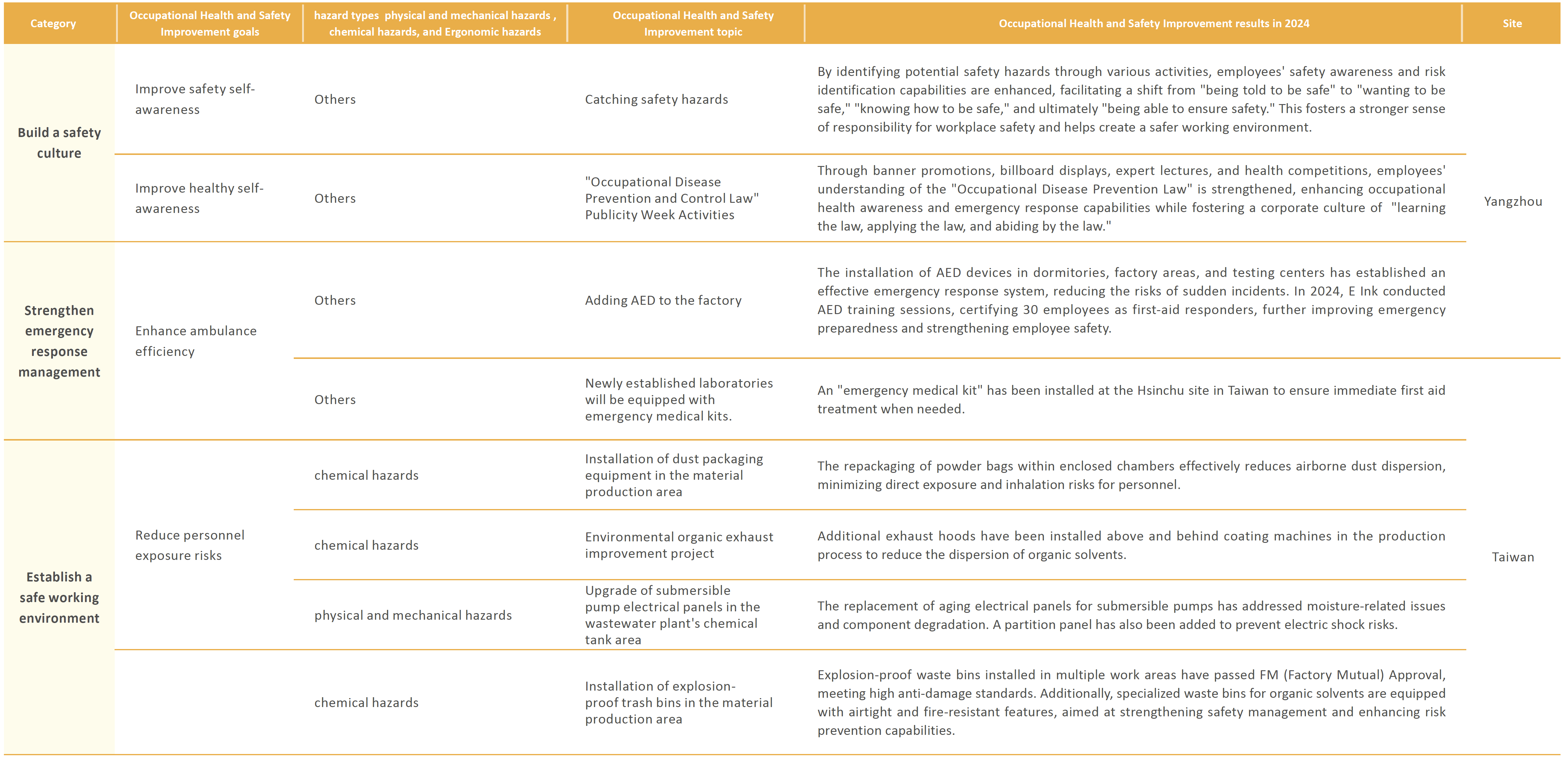

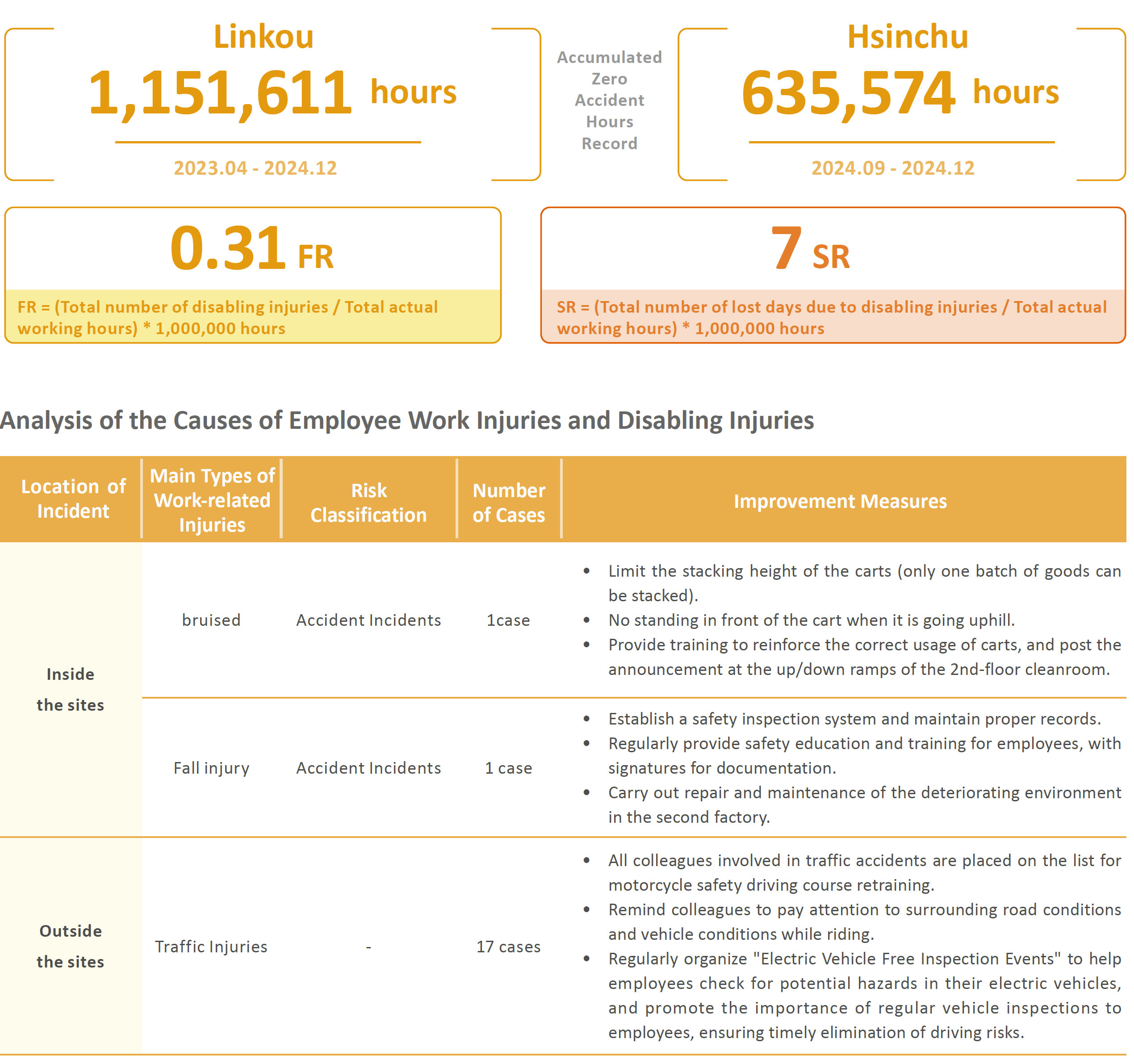

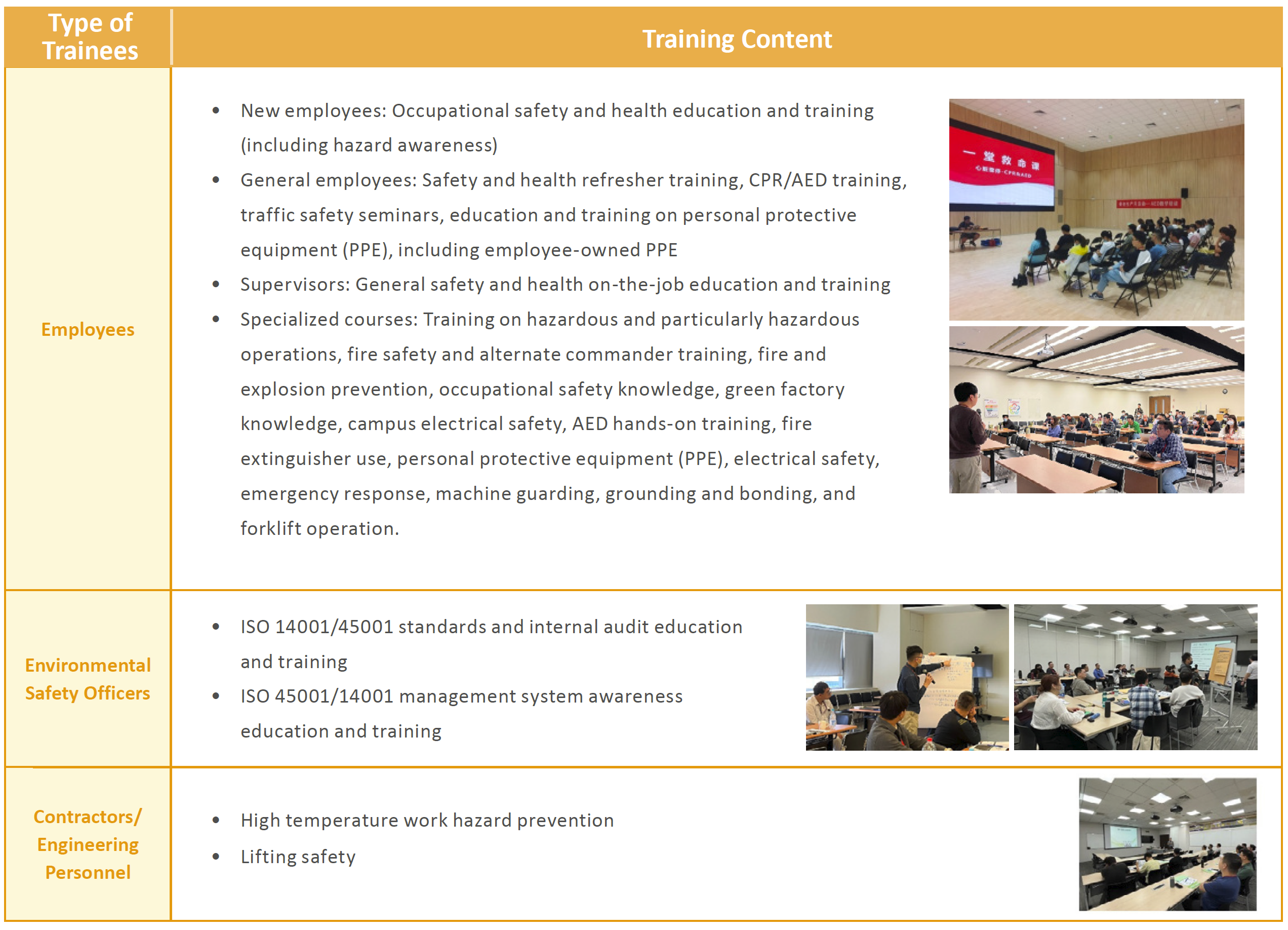

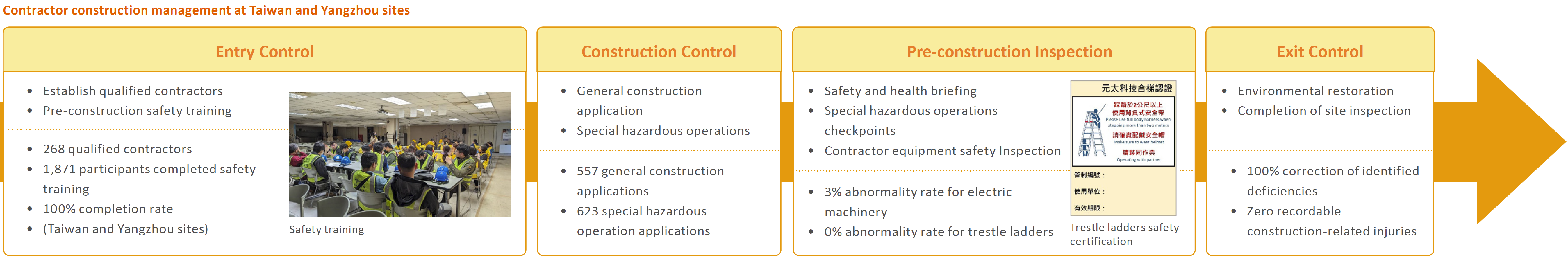

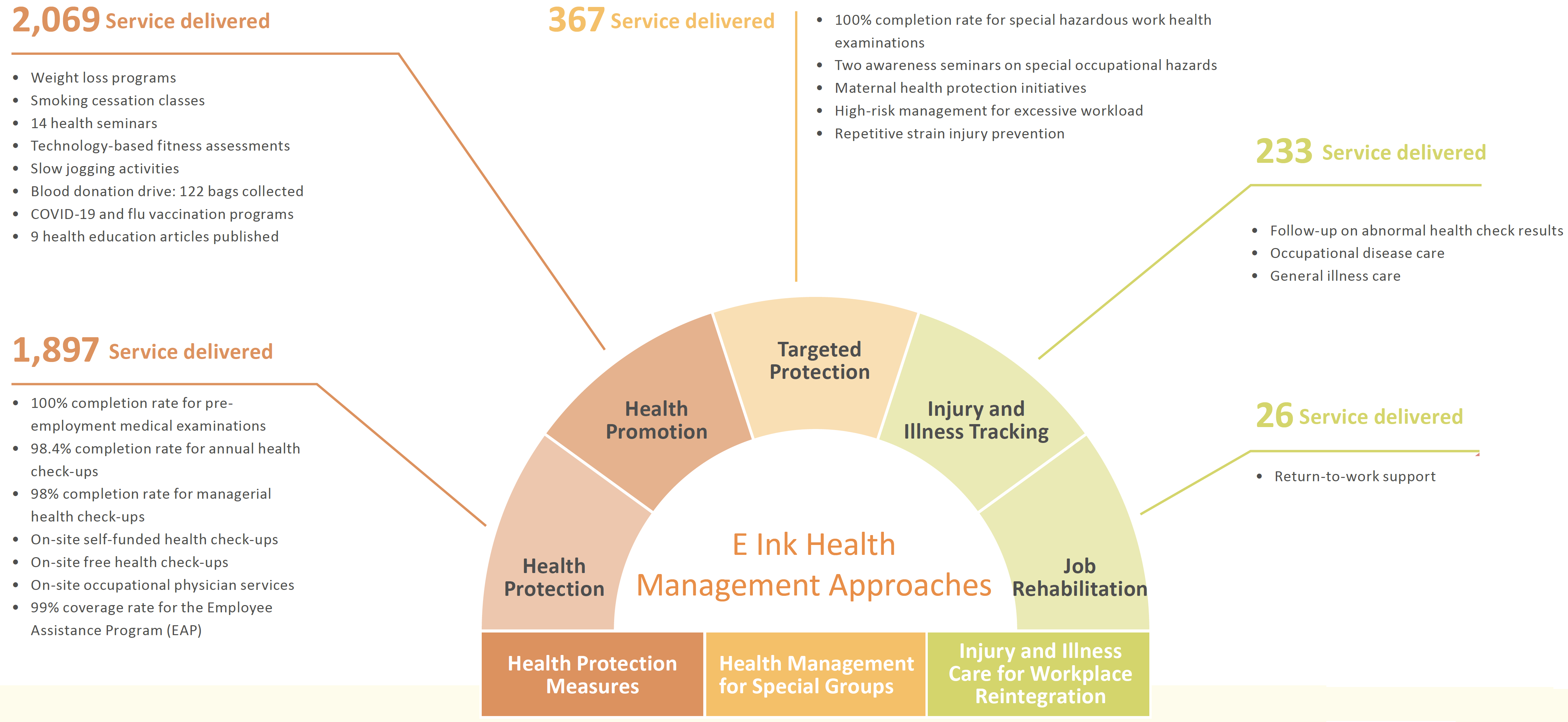

E Ink upholds the core values of "Safety First, Environmental Protection Priority, Full Participation, and Sustainable Operation" by establishing a comprehensive " Safety, Health, Environment, and Energy Management." This policy aims to create a healthy, safe, and comfortable work environment for employees. By implementing the ISO 45001 Occupational Health and Safety Management System, E Ink focuses on safety as a priority, integrating safety protection, environmental improvement, and health care into three main aspects. The strategies include enhancing management empowerment through occupational safety systems, controlling risks to create a secure workplace, promoting a safety culture, and fostering a healthy and enjoyable work environment. These efforts aim to mitigate or reduce risks, prevent fatalities, decrease work-related injuries, ensure employee health, and continuously improve occupational health and safety (OHS) performance.