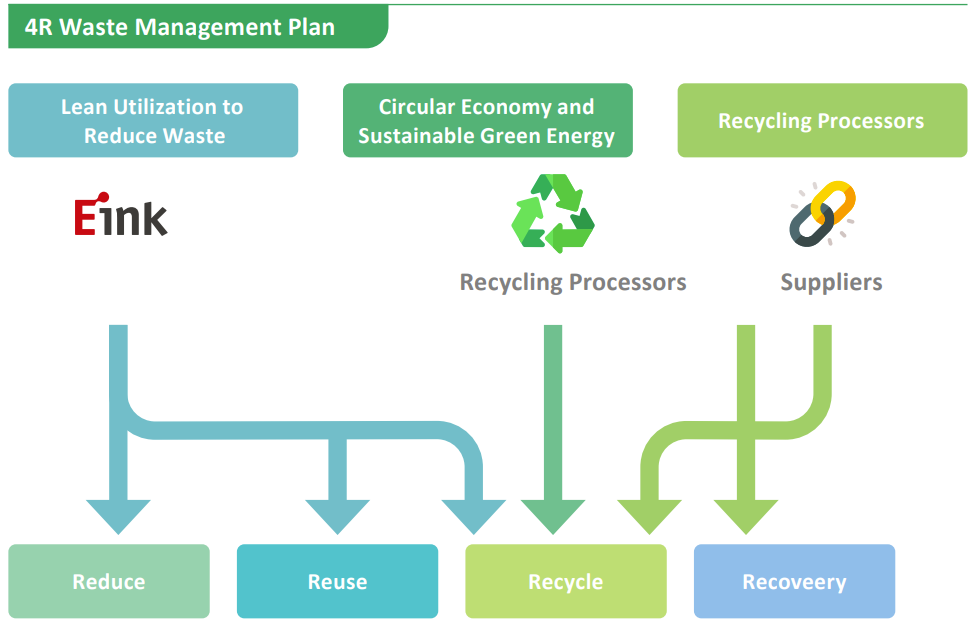

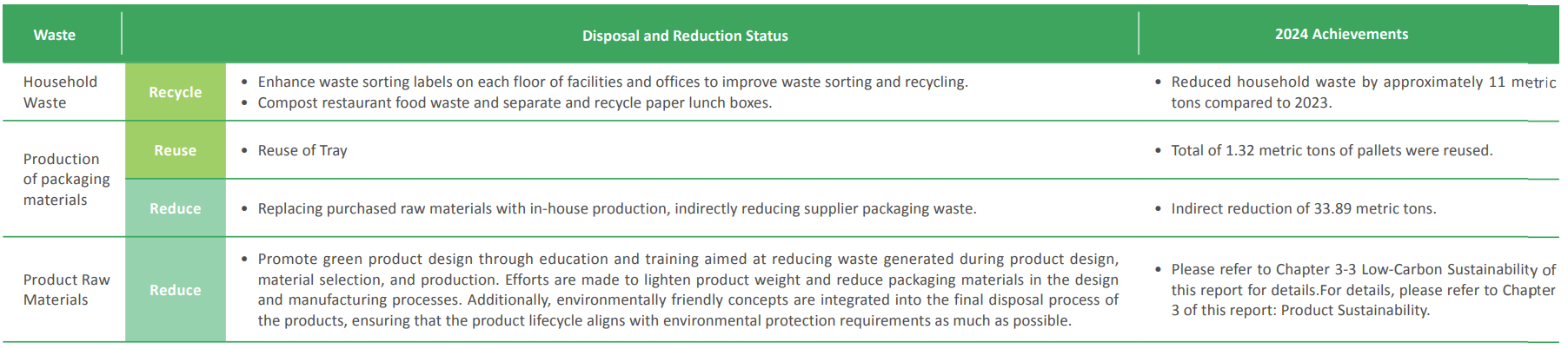

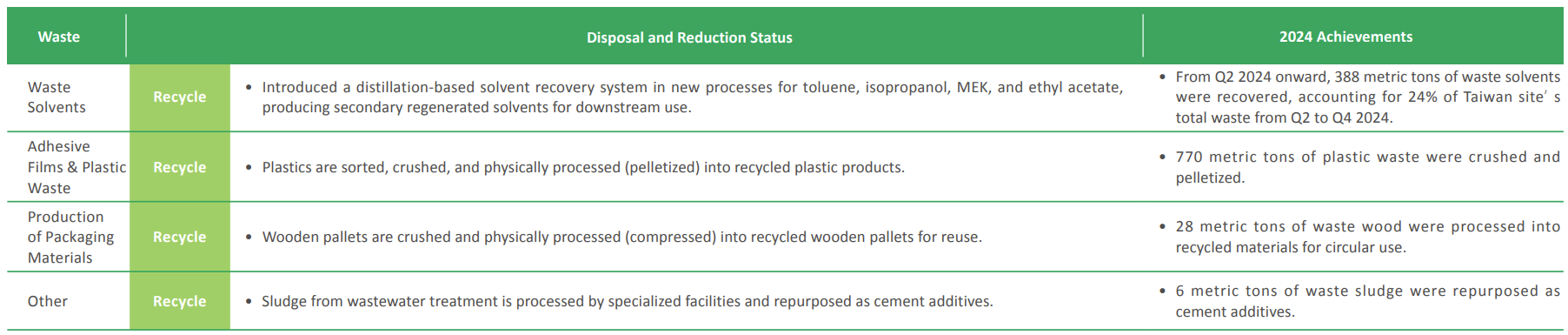

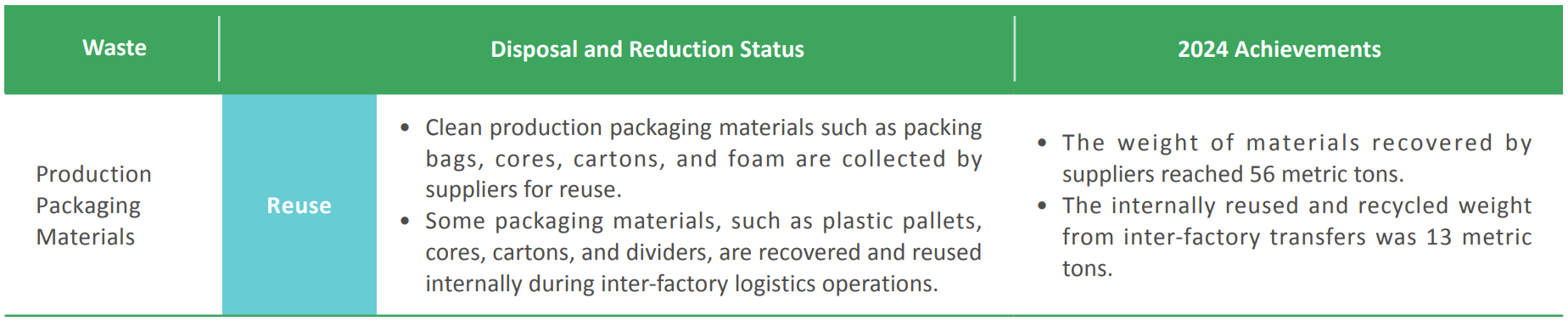

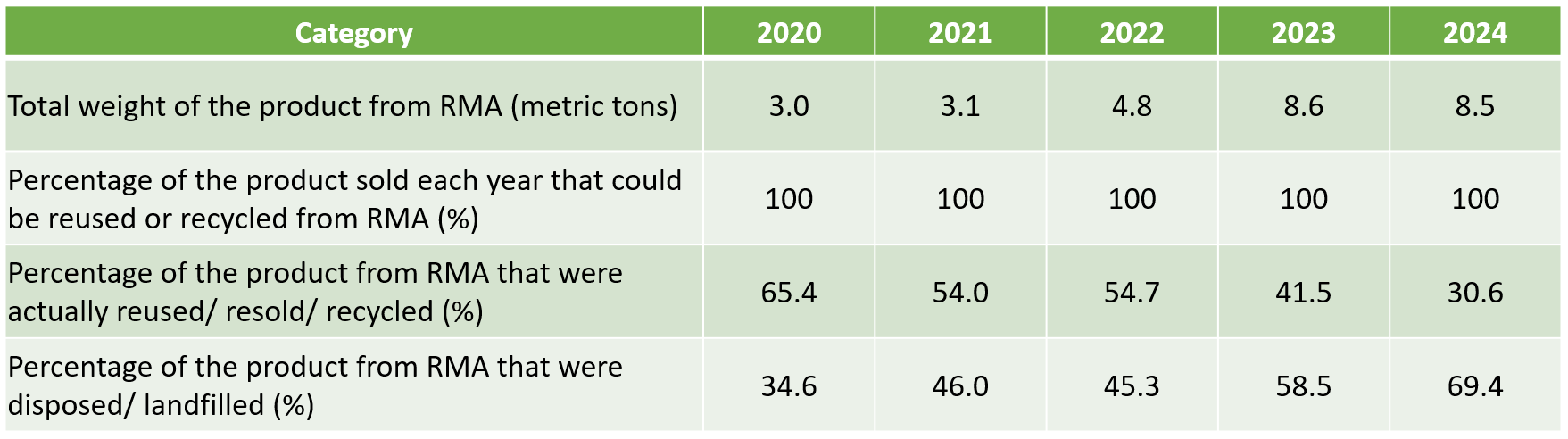

To reduce the overall waste generation and the proportion of waste treated by incineration and thermal recovery, E Ink collaborates with suppliers and recycling processors to jointly promote the 4R waste management plan (Reduce, Reuse, Recycle, Recovery). By formulating strategies such as lean utilization to reduce waste, circular economy and sustainable green energy, and proper disposal through recycling, the Company prioritizes converting waste that would otherwise be treated by thermal recovery and landfill, achieving waste reduction and management goals.

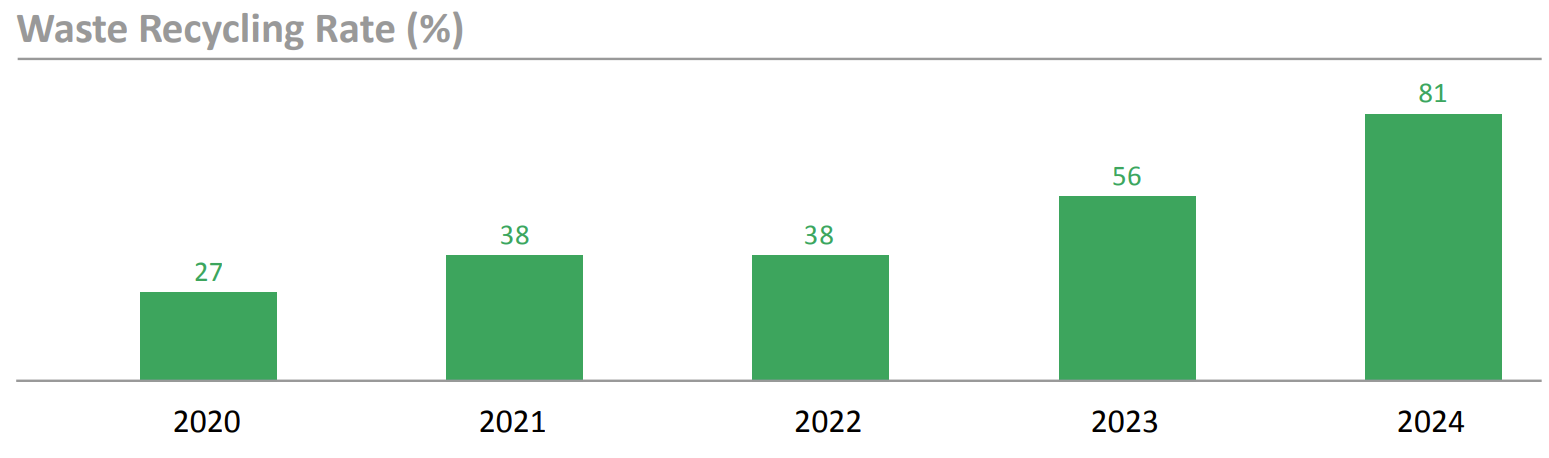

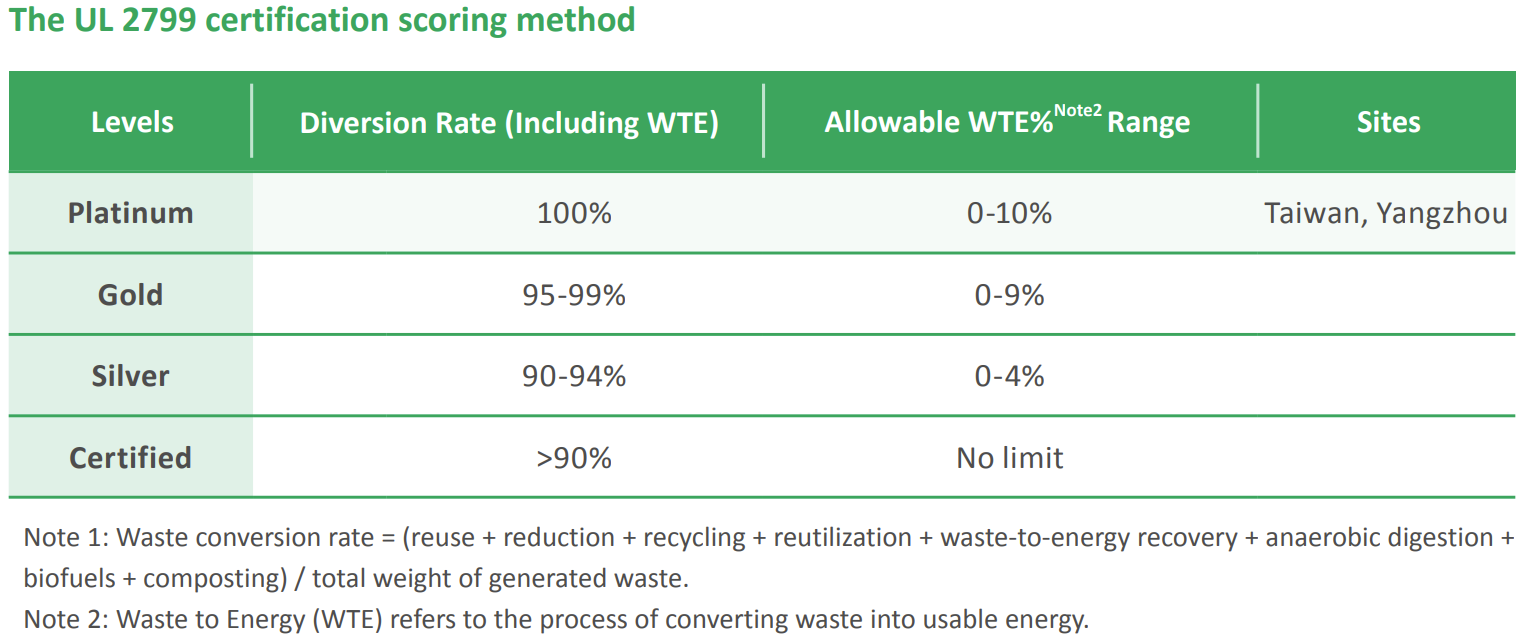

As global attention on environmental protection and sustainable development continues to grow, how businesses effectively manage resources and reduce waste has become a key issue. To address this, E Ink has been promoting the UL 2799 Zero Waste to Landfill certification since 2019, aiming to increase the proportion of waste recycled, reused, or converted, and to avoid landfill disposal or incineration without energy recovery, in pursuit of a zero-waste goal.

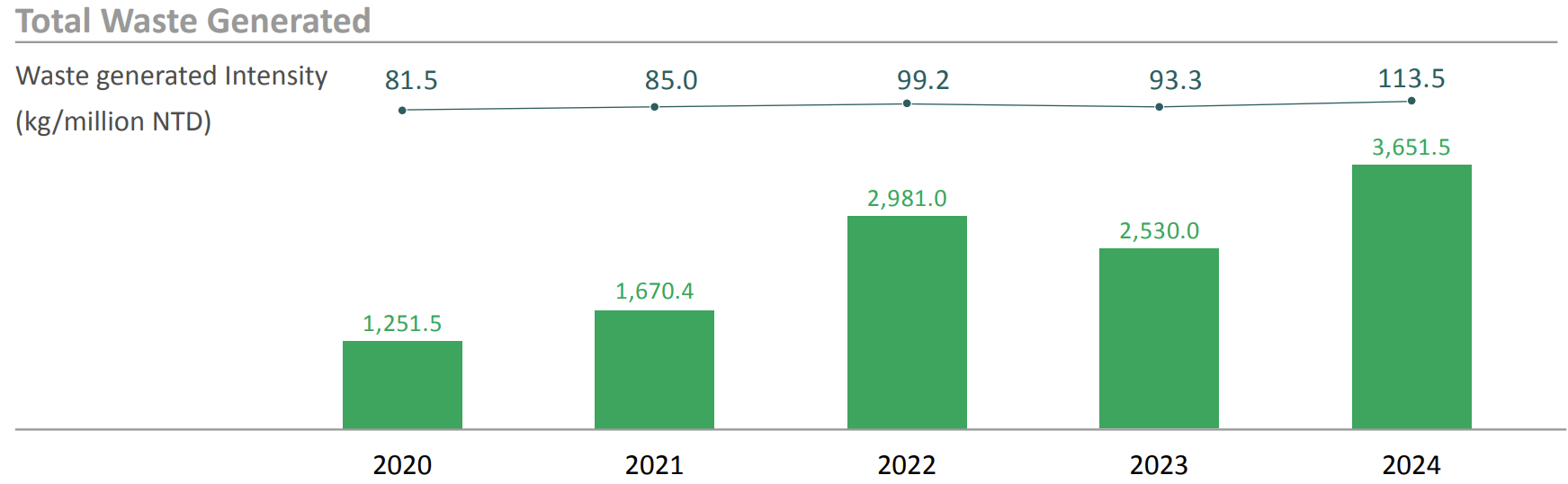

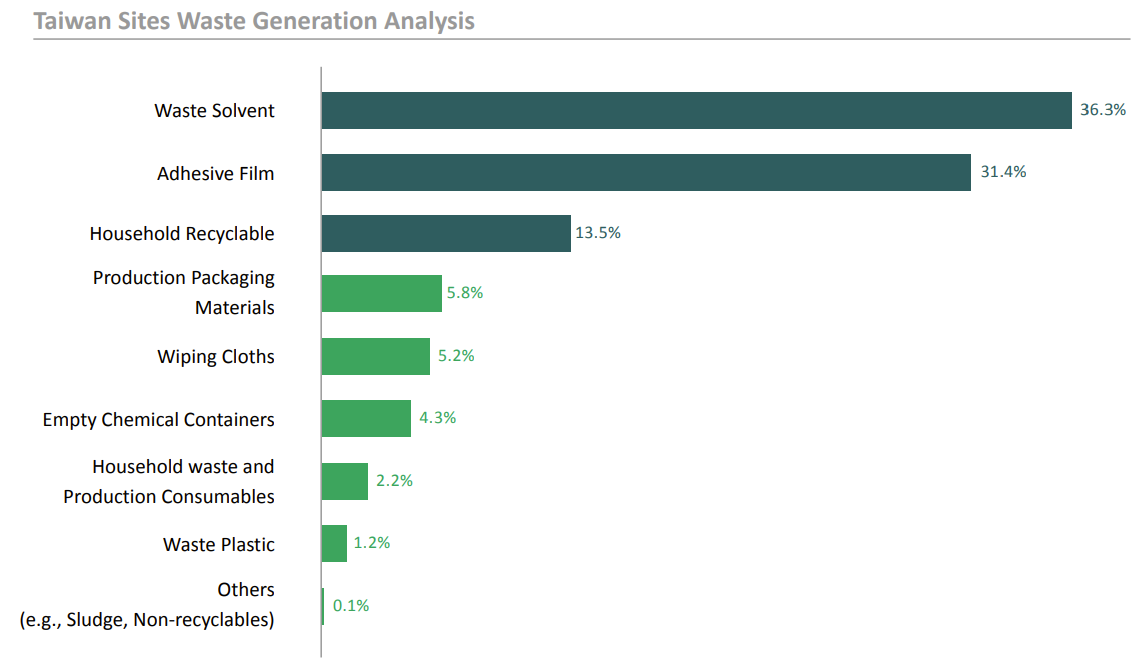

E Ink's primary sources of waste include waste solvents, adhesive plastic film, household recyclable materials, and production packaging materials, which account for over 80% of the total waste by weight. In the past, this waste was primarily handled through incineration, a process that produces a large amount of carbon dioxide and adds additional environmental burden. To reduce carbon emissions and improve resource utilization efficiency, E Ink has strengthened its waste management measures starting in 2024, improving sorting operations and actively promoting waste recycling and reuse to establish a more sustainable waste treatment model.