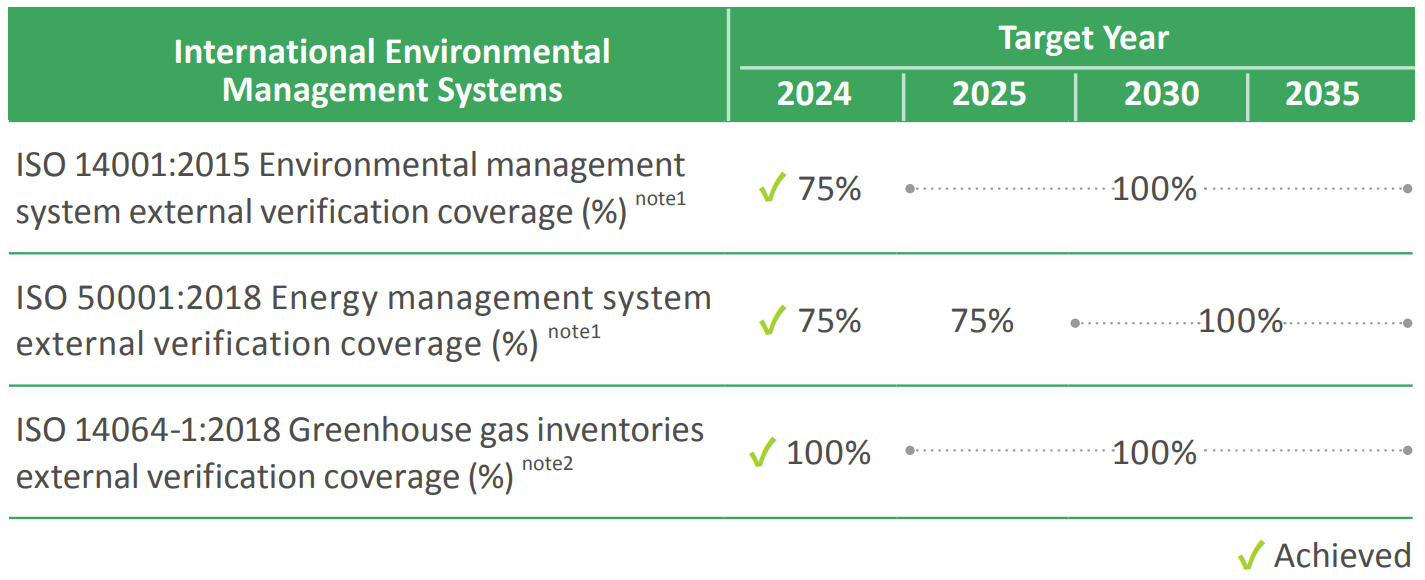

Progress

To enhance environmental management across its global production sites and offices, E Ink plans to establish systems aligned with ISO 14001, ISO 50001, and ISO 14064-1 standards, aiming to obtain external certification or verification by 2030. Notably, 100% of E Ink’s global production sites have been successfully certified under ISO 14001, a significant milestone in the Company’s commitment to international environmental management standards.

Note 1: By 2025, the scope will cover E Ink's four global production sites, including the Hsinchu and Linkou sites in Taiwan, the Yangzhou sites, and the South Hadley site in the US. After 2026, E Ink plans to increase the number of operational production sites from four to five.

Note 2: This scope includes the operational, production, and sales sites of E Ink and its subsidiaries consolidated in the financial statements.