Strengthen Restricted and Hazardous Substances Management

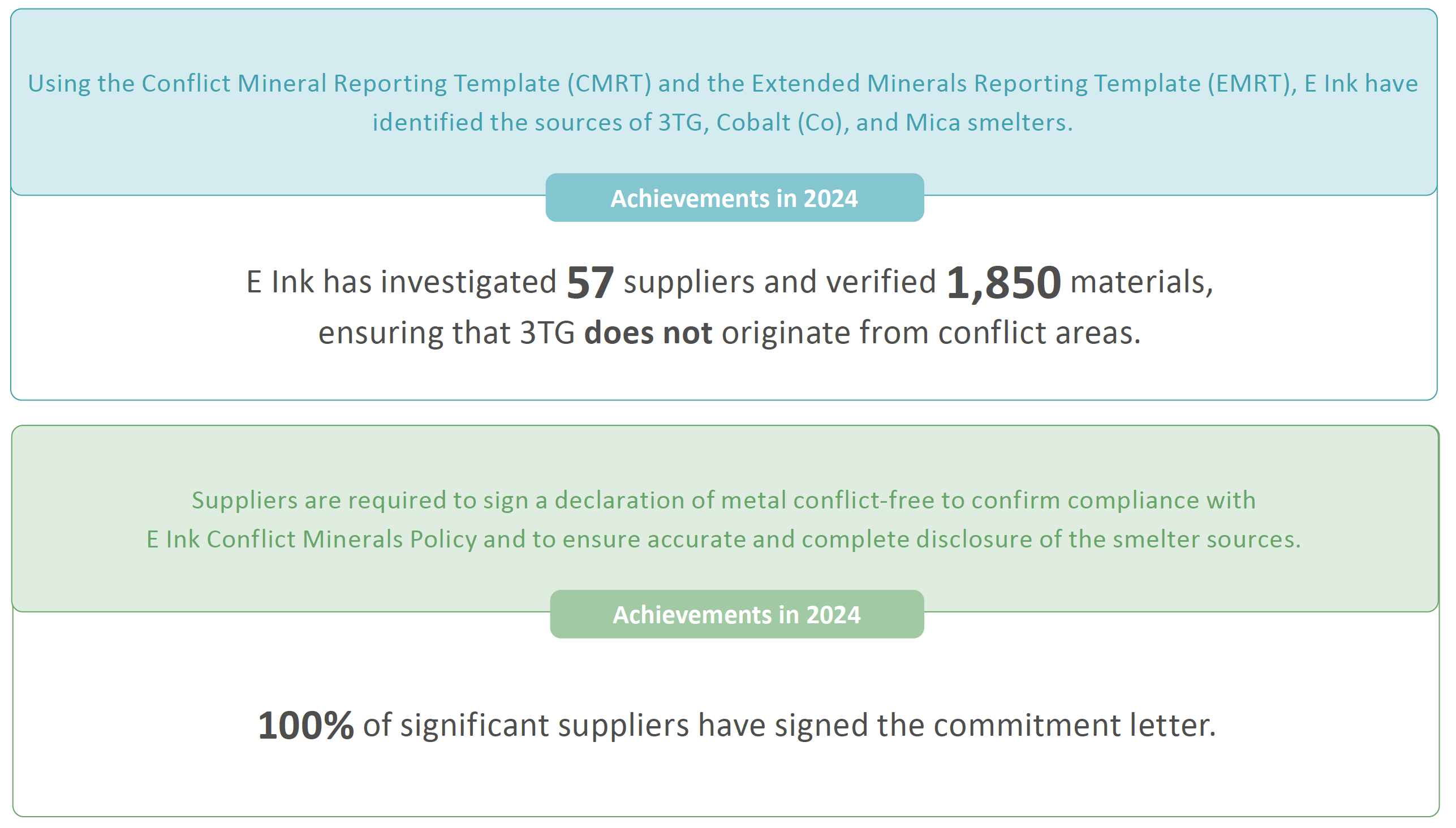

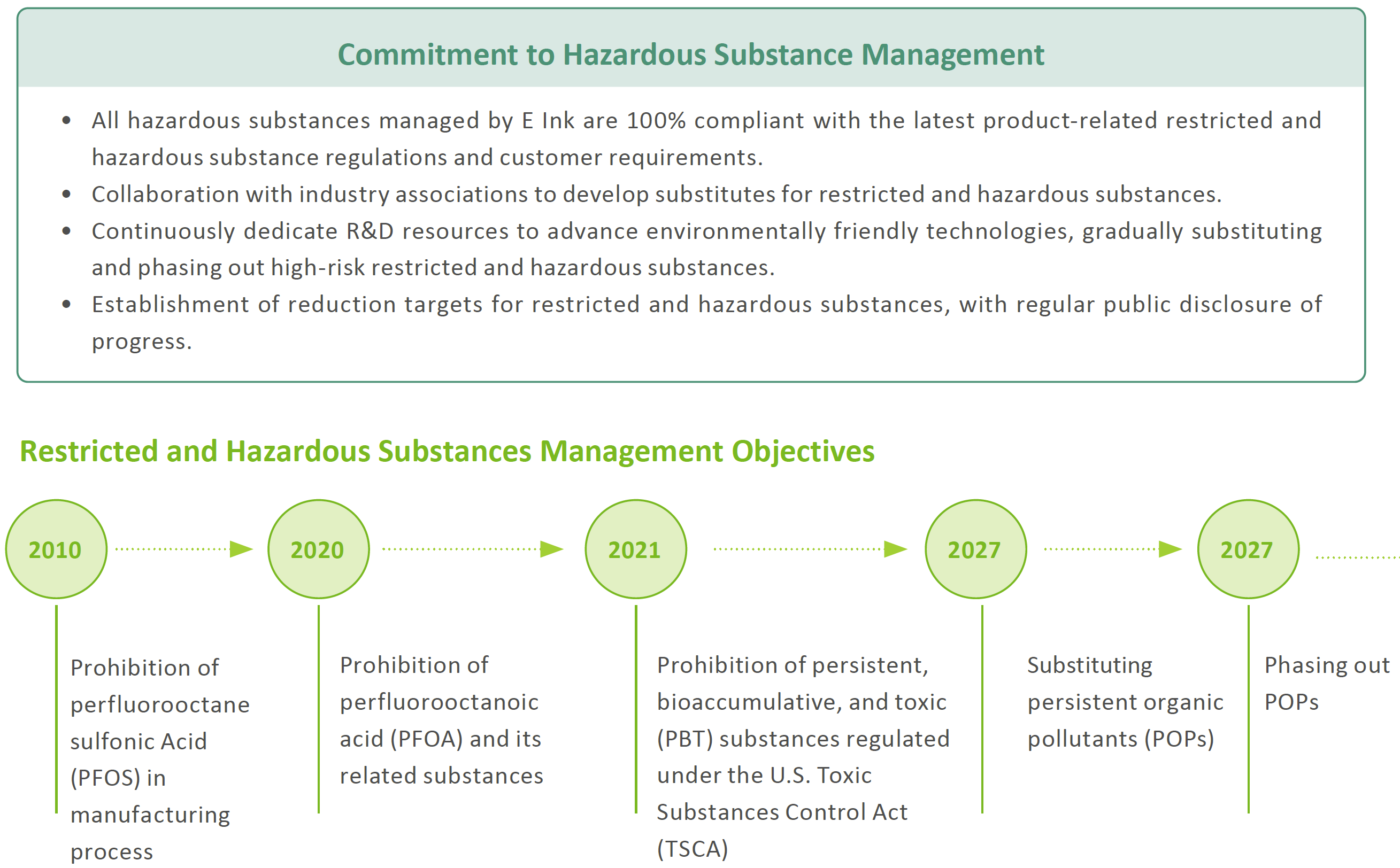

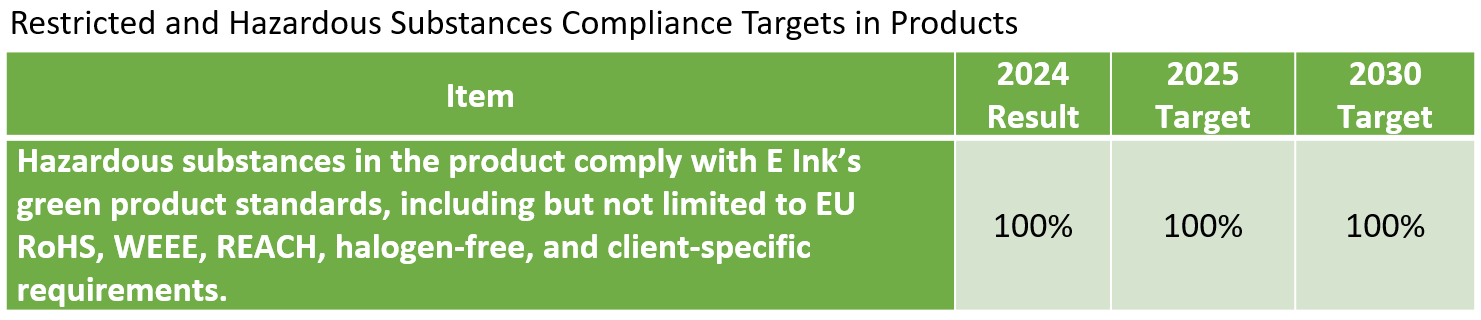

E Ink is committed to providing products that meet customer needs while being environmentally friendly, adhering to the management principles of "No Entry, No Use, No Output" for hazardous substances. Strict controls are implemented at every stage, from product design, raw material procurement, and manufacturing to production testing and final sales, ensuring compliance with current domestic and international regulations and commitments on hazardous substance management. E Ink currently manages restricted substances in accordance with the Restriction of Hazardous Substances Directive (RoHS), the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH), the prohibition of conflict minerals, and Halogen Free requirements. No noncompliance issues were identified in 2024Note. Additionally, E Ink incorporates specific customers' restricted substance regulations into its controlled substance list after thorough review to further strengthen management. In 2025, E Ink plans to incorporate Persistent Organic Pollutants (POPs) and Per- and Polyfluoroalkyl Substances (PFAS) into its management scope and will continue to monitor key restricted substance regulations in its product markets to ensure compliance with the latest environmental regulations and customer requirements.

In 2021, E Ink's "Environmental Restricted Substances Management Committee" established the "Green Product" management guidelines, implementing comprehensive control over all components through the restricted and hazardous substances management process. In addition to regularly holding meetings and reviewing operations to ensure that management standards remain up-to-date, the committee also evaluates customer requests or changes in international restricted and hazardous substance regulations, adjusting control standards and operational modes as needed, and notifying relevant departments through announcements. If restricted substances are found in products, a phased-out or substitution will be developed.

Note: All raw materials must comply with E Ink's restricted substances management regulations. E Ink may require material suppliers to provide and update third-party certified restricted substances test reports, and also conducts annual sampling tests of materials for restricted substances through a third-party certified body to ensure compliance with its restricted substances management regulations.